新聞中心

滾珠絲杠和直線電機的對比分析

來源:http://www.idczc.com/ 日期:2021-03-10 發(fā)布人:

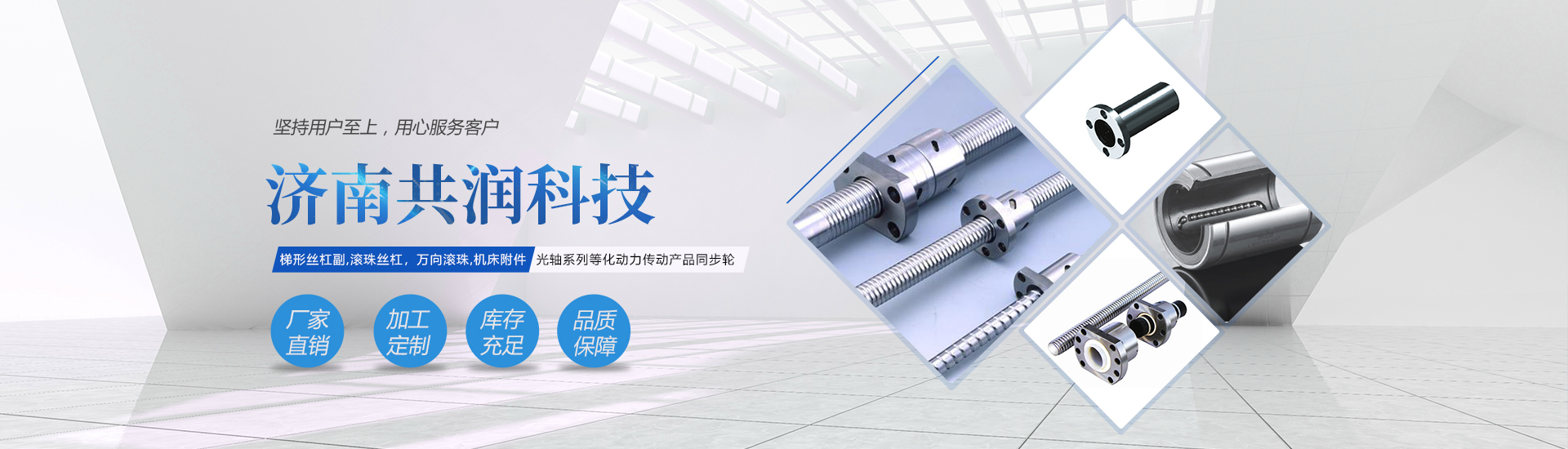

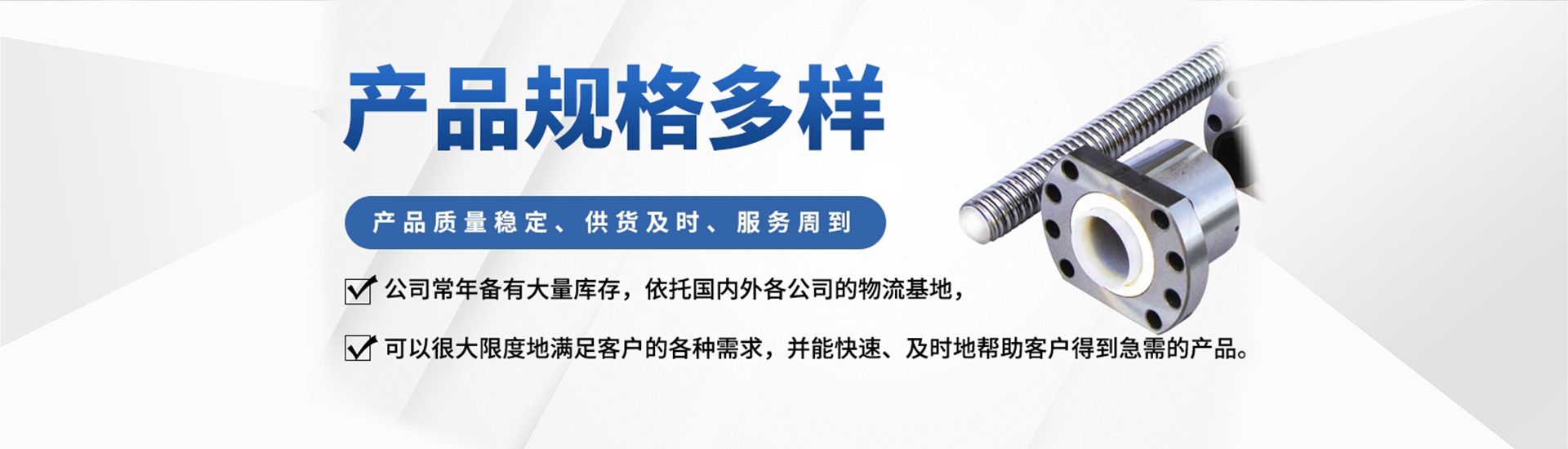

滾珠絲杠是機床和精密機械中 常用的傳動部件。其主要功能是將旋轉(zhuǎn)運動轉(zhuǎn)換為直線運動,或?qū)⑴ぞ剞D(zhuǎn)換為軸向重復(fù)力,具有高精度,可逆性和率的特點。自滾珠絲杠開發(fā)以來,它已廣泛應(yīng)用于精密機床,工業(yè)機械,電子機械,輸送機械等各種工業(yè)機械的定位精度控制。

Ball screw is a common transmission part in machine tools and precision machinery. Its main function is to convert rotary motion into linear motion or torque into axial repetitive force. It has the characteristics of high precision, reversibility and high efficiency. Since the development of ball screw, it has been widely used in precision machine tools, industrial machinery, electronic machinery, conveying machinery and other industrial machinery positioning accuracy control.

直線電機,也稱為直線電機,是各種領(lǐng)域制造商常用的一種機械設(shè)備。通過將它們安裝在生產(chǎn)設(shè)備上,可以為企業(yè)的生產(chǎn)線提供高速自動直線運動,可以有效提高企業(yè)的生產(chǎn)能力。直線滑臺電機的特點是直線運動,而滾動螺桿和旋轉(zhuǎn)電機間接產(chǎn)生直線運動。

Linear motor, also known as linear motor, is a kind of mechanical equipment commonly used by manufacturers in various fields. By installing them on the production equipment, it can provide high-speed automatic linear motion for the production line of the enterprise, which can effectively improve the production capacity of the enterprise. Linear slide motor is characterized by linear motion, while rolling screw and rotary motor produce linear motion indirectly.

導(dǎo)軌絲杠

Guide screw

讓我們導(dǎo)軌絲杠小編對這兩者的主要特征進行一些比較:

Let's compare the main features of the two

1、速度,直線電機在速度方面具有相當(dāng)大的優(yōu)勢。直線電機的速度為300m / min;加速度為5G。滾珠絲杠的速度為100m/min。從速度和加速度的比較來看,直線電機具有相當(dāng)大的優(yōu)勢,并且直線電機在成功解決加熱問題后將進一步提高速度,并且"旋轉(zhuǎn)伺服電動機+滾珠絲杠"的速度受到更多限制。很難改進。在動態(tài)響應(yīng)方面,由于運動慣性和間隙以及機構(gòu)復(fù)雜性等問題,直線電機具有的優(yōu)勢。

1. Speed, linear motor has a considerable advantage in speed. The speed of the linear motor is 300m / min and the acceleration is 5g. The speed of ball screw is 100 m / min. From the comparison of speed and acceleration, the linear motor has considerable advantages, and the linear motor will further improve the speed after successfully solving the heating problem, and the speed of "rotary servo motor + ball screw" is more limited. It's hard to improve. In terms of dynamic response, linear motor has absolute advantages due to the problems of motion inertia, clearance and mechanism complexity.

2、在速度控制方面,直線電機響應(yīng)速度更快,速度范圍更寬, 高可達1:10000,可以在開始時達到 大速度,并且可以高速快速停止。

2. In terms of speed control, the linear motor has a faster response speed and a wider speed range, up to 1:10000, which can reach a large speed at the beginning and stop at a high speed.

導(dǎo)軌絲杠

Guide screw

a、準確性,在精度方面,直線電機由于傳動機構(gòu)而具有簡單的內(nèi)插滯后減小。通過位置檢測反饋控制,定位精度,再現(xiàn)精度和精度高于"旋轉(zhuǎn)伺服電機+滾珠絲杠",并且易于實現(xiàn)。 旋轉(zhuǎn)伺服電機+滾珠絲杠"是一種增壓傳動部件。當(dāng)提供相同的扭矩時,線性馬達消耗的能量是"旋轉(zhuǎn)伺服馬達+滾珠螺桿"的兩倍。而且,直線電機的可靠性受控制系統(tǒng)穩(wěn)定性的影響,對周圍環(huán)境影響很大。因此,必須采取有效的磁隔離和保護措施來阻止磁場對滾動導(dǎo)軌的影響和銑屑磁塵的吸附。

a. In the aspect of accuracy, the linear motor has a simple interpolation lag reduction due to the transmission mechanism. Through the position detection feedback control, the positioning accuracy, reproduction accuracy and absolute accuracy are higher than that of "rotary servo motor + ball screw", and easy to realize. "Rotary servo motor + ball screw" is a kind of energy-saving supercharging transmission parts. When providing the same torque, the energy consumption of linear motor is twice that of "rotary servo motor + ball screw". Moreover, the reliability of the linear motor is affected by the stability of the control system, which has a great impact on the surrounding environment. Therefore, effective magnetic isolation and protection measures must be taken to prevent the influence of magnetic field on rolling guide rail and the adsorption of milling dust.

b、直線電機噪音低,因為直線電機不受離心力的約束,運動過程中沒有機械接觸,沒有摩擦和噪音。傳動部件不磨損,可大大減少機械損失,避免拖纜,電纜,齒輪,皮帶輪產(chǎn)生的噪音,提高整體效率。經(jīng)過長時間的使用,滾珠絲杠在滾珠表面剝落,或滾珠絲杠軸有切割力表面的問題,間接影響滾珠的運行軌跡,造成滾珠間的摩擦,螺母和軸引起振動。這樣噪音太大了。

b. The noise of linear motor is low, because linear motor is not constrained by centrifugal force, there is no mechanical contact, friction and noise in the process of movement. The transmission parts are not worn, which can greatly reduce the mechanical loss, avoid the noise generated by the streamer, cable, gear and pulley, and improve the overall efficiency. After a long time of use, the ball screw peels off on the surface of the ball, or the ball screw shaft has cutting force on the surface, which indirectly affects the trajectory of the ball, causing friction between the balls, and vibration between the nut and the shaft. It's too noisy.

導(dǎo)軌絲杠

Guide screw

c、行程:直線電機有效行程無限制,滾珠絲杠的螺母運行到有效行程后,仍然可以正常旋轉(zhuǎn),但在正常情況下,不能過度旋轉(zhuǎn),否則會損壞滾珠絲杠,導(dǎo)致大量的滾珠顆粒和螺母掉落關(guān)閉。

c. Stroke: there is no limit to the effective stroke of linear motor. The nut of ball screw can still rotate normally when it reaches the effective stroke, but under normal circumstances, excessive rotation is not allowed, otherwise the ball screw will be damaged and a large number of ball particles and nuts will fall off and close.

以上內(nèi)容導(dǎo)軌絲杠小編由整理,更多詳情咨詢請關(guān)注我們http://www.idczc.com

The above contents are arranged by the guide screw editor. Please pay attention to us for more details http://www.idczc.com

導(dǎo)軌絲杠:從設(shè)計結(jié)構(gòu)...<>

導(dǎo)軌絲杠:從設(shè)計結(jié)構(gòu)...<> 大型絲杠的性能設(shè)計介...<>

大型絲杠的性能設(shè)計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業(yè)的...<>

滾珠絲桿目前的行業(yè)的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關(guān):