新聞中心

滾珠絲桿和直線導(dǎo)軌的特性區(qū)別在哪里?

來源:http://www.idczc.com/ 日期:2021-09-08 發(fā)布人:

滾珠絲桿的特性

Characteristics of ball screw

1、與滑動絲桿副相比驅(qū)動力矩為1/3

1. Compared with the sliding screw pair, the driving torque is 1 / 3

由于滾珠絲桿副的絲桿軸與絲母之間有很多滾珠在做滾動運動,所以能得到較高的運動效率.與過去的滑動絲桿副相比驅(qū)動力矩達到1/3以下,即達到同樣運動結(jié)果所需的動力為使用滾動絲桿副的1/3.在省電方面很有幫助。

Because there are many balls rolling between the screw shaft and the screw nut of the ball screw pair, higher motion efficiency can be obtained. Compared with the past sliding screw pair, the driving torque is less than 1 / 3, that is, the power required to achieve the same motion result is 1 / 3 of that of the rolling screw pair. It is very helpful in power saving.

2、高精度的保證

2. Guarantee of high precision

滾珠絲桿副是用世界高水平的機械設(shè)備連貫生產(chǎn)出來的,特別是在研削、組裝、檢查各工序的工廠環(huán)境方面,對溫度·濕度進行了嚴格的控制,由于完善的品質(zhì)管理體制使精度得以充分保證.

Ball screw pairs are produced continuously with world-class mechanical equipment, especially in the factory environment of grinding, assembly and inspection processes. The temperature and humidity are strictly controlled. The accuracy is fully guaranteed due to the perfect quality management system

3、微進給可能

3. Micro feed possible

滾珠絲桿副由于是利用滾珠運動,所以啟動力矩極小,不會出現(xiàn)滑動運動那樣的爬行現(xiàn)象,能保證實現(xiàn)精 確的微進給.

Because the ball screw pair uses ball motion, the starting torque is very small, there will be no crawling phenomenon such as sliding motion, and can ensure accurate micro feeding

4、無側(cè)隙、剛性高

4. No backlash, high rigidity

滾珠絲桿副可以加予壓,由于予壓力可使軸向間隙達到負值,進而得到較高的剛性(滾珠絲桿內(nèi)通過給滾珠加予壓力,在實際用于機械裝置等時,由于滾珠的斥力可使絲母部的剛性增強).

The ball screw pair can be preloaded. Due to the preloading, the axial clearance can reach a negative value, so as to obtain high rigidity (by preloading the ball in the ball screw, when it is actually used in mechanical devices, the rigidity of the nut can be enhanced due to the repulsive force of the ball)

5、高速進給可能

5. High speed feed possible

滾珠絲桿由于運動效率高、發(fā)熱小、所以可實現(xiàn)高速進給(運動)。

The ball screw can realize high-speed feeding (movement) because of its high movement efficiency and low heating.

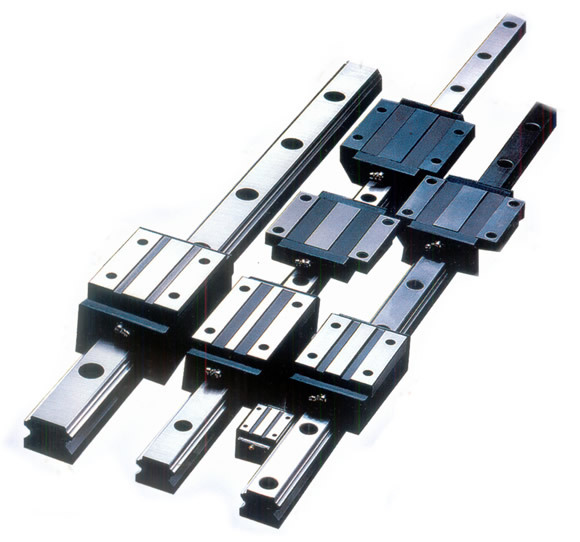

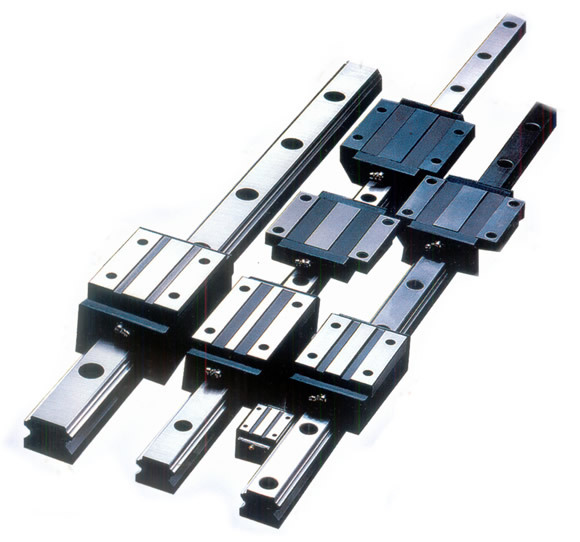

直線導(dǎo)軌的特性

Characteristics of linear guide

1、定位精度高使用直線導(dǎo)軌作為線性導(dǎo)引時,由于直線導(dǎo)軌的摩擦方式為滾動摩擦,不僅摩擦系數(shù)降低滑動導(dǎo)引的1/50,動摩擦力與靜摩擦力的差距亦變得很小,因此當床臺運動時,不會有打滑的現(xiàn)象發(fā)生,可達到超 高 精 密級(um)級定為精度。

1. High positioning accuracy when using the linear guide rail as the linear guide, because the friction mode of the linear guide rail is rolling friction, not only the friction coefficient is reduced to 1 / 50 of the sliding guide, but also the gap between dynamic friction and static friction becomes very small. Therefore, when the bed moves, there will be no sliding phenomenon, and the ultra-high precision level (UM) can be achieved.

2、磨耗少能長時間維持精度傳統(tǒng)的滑動引導(dǎo),無可避免的會因油膜逆流作用造成平臺運動精度不好,且因運動時潤滑不充份,導(dǎo)致運行軌道接觸面的磨損,嚴重影響精度,而滾動導(dǎo)引的磨耗非常小,故機臺能長時間維持精度。

2. Less wear can maintain the accuracy for a long time. The traditional sliding guidance will inevitably cause poor motion accuracy of the platform due to the countercurrent effect of oil film, and the insufficient lubrication during movement will lead to the wear of the contact surface of the running track, which seriously affects the accuracy. However, the wear of rolling guidance is very small, so the machine can maintain the accuracy for a long time.

3、使用高速度運動且大幅降低機臺所需驅(qū)動馬力由于直線導(dǎo)軌移動摩擦力非常小,只需較小動力便能讓床臺運行,尤其是在床臺的工作方式為經(jīng)常性往返運動時,更能明顯降低機臺點力損耗量,且因其摩擦產(chǎn)生的熱度較小,可適用于高速運行。

3. Use high-speed movement and greatly reduce the driving horsepower required by the machine. Because the moving friction of the linear guide rail is very small, the bed can be operated with less power. Especially when the working mode of the bed is regular round-trip movement, it can significantly reduce the point force loss of the machine, and the heat generated by its friction is small, so it is suitable for high-speed operation.

4、可同時承受上下左右的負荷由于直線導(dǎo)軌特殊的束制結(jié)構(gòu)設(shè)計,可同時承受上下左右方向的負荷,不想滑動導(dǎo)引在平行接觸面方向可承受的側(cè)向負荷輕,易造成機臺運行精度不好。

4. It can bear up, down, left and right loads at the same time. Due to the special beam structure design of the linear guide rail, it can bear the loads in the up, down, left and right directions at the same time. It does not want to slide and guide. The lateral load that can be borne in the direction parallel to the contact surface is light, which is easy to cause poor operation accuracy of the machine.

5、組裝容易并具互換性組裝時只要銑削或研磨床臺上導(dǎo)軌之裝配面,并依建議之步驟將導(dǎo)軌,滑塊分別特定扭力固定于機臺上,既能重視加工時的高精度,傳統(tǒng)的滑動導(dǎo)引,則須對運行軌道加以鏟花,既費事又費時,且一旦機臺精度良,又必 須在鏟花一次,直線導(dǎo)軌具有互換性,可分別更換滑塊或?qū)к壥侵本€導(dǎo)軌組,機臺即可重新獲得高精 密度的引導(dǎo)。

5. The assembly is easy and interchangeable. During assembly, as long as the assembly surface of the guide rail on the machine table is milled or grinded, and the specific torque of the guide rail and sliding block are fixed on the machine table according to the recommended steps, it can not only pay attention to the high precision during processing, but also the traditional sliding guidance, the running track must be scratched, which is both time-consuming and time-consuming. Once the machine table precision is good, it must be scratched again, The linear guide rail is interchangeable. The sliding block or guide rail can be replaced to the linear guide rail group respectively, and the machine can regain high-precision guidance.

6、潤滑結(jié)構(gòu)簡單滑動引導(dǎo)若潤滑不足,將會照成接觸面金屬直接摩擦損耗床臺,而滑動導(dǎo)引要潤滑充足并不容易,需要在床臺適當?shù)奈恢勉@孔供油,直線導(dǎo)軌則已在裝置油嘴,可直接以注油槍打入油脂,亦可換上專用油管接頭鏈接供油油管,以自動供油機潤滑。

6. The lubrication structure is simple. If the sliding guide is not lubricated enough, it will cause direct friction loss of the metal on the contact surface of the bed. However, it is not easy for the sliding guide to be lubricated enough. It is necessary to drill holes at the appropriate position of the bed for oil supply. The linear guide rail has been installed at the oil nozzle of the device, and the grease can be directly injected with the oil gun. It can also be replaced with a special oil pipe joint to link the oil supply pipe to lubricate the automatic oil supply machine.

導(dǎo)軌絲杠:從設(shè)計結(jié)構(gòu)...<>

導(dǎo)軌絲杠:從設(shè)計結(jié)構(gòu)...<> 大型絲杠的性能設(shè)計介...<>

大型絲杠的性能設(shè)計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業(yè)的...<>

滾珠絲桿目前的行業(yè)的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關(guān):