新聞中心

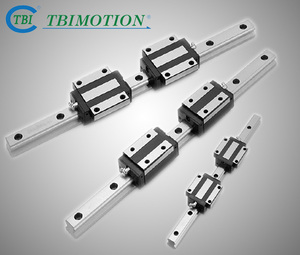

導(dǎo)軌絲杠有哪些分類(lèi)

來(lái)源:http://www.idczc.com/ 日期:2021-11-11 發(fā)布人:

根據(jù)軸承的工作原理可分:滾動(dòng)摩擦軸承(滾動(dòng)軸承)和滑動(dòng)摩擦軸承(滑動(dòng)軸承)。

According to the working principle of bearing, it can be divided into rolling friction bearing (rolling bearing) and sliding friction bearing (sliding bearing).

滑動(dòng)軸承:在滑動(dòng)軸承表面若能形成潤(rùn)滑膜將運(yùn)動(dòng)副表面分開(kāi),則滑動(dòng)摩擦力可大大降低,由于運(yùn)動(dòng)副表面不直接接觸,因此也避免了磨損。滑動(dòng)軸承的承載能力大,回轉(zhuǎn)精度高,潤(rùn)滑膜具有抗沖擊作用,因此,在工程上獲得廣泛的應(yīng)用。

Sliding bearing: if a lubricating film can be formed on the surface of the sliding bearing to separate the surface of the moving pair, the sliding friction can be greatly reduced. Since the surface of the moving pair is not in direct contact, wear is also avoided. Sliding bearing has large bearing capacity, high rotation precision and anti impact effect of lubricating film. Therefore, it has been widely used in engineering.

潤(rùn)滑膜的形成是滑動(dòng)軸承能正常工作的基本條件,影響潤(rùn)滑膜形成的因素有潤(rùn)滑方式、運(yùn)動(dòng)副相對(duì)運(yùn)動(dòng)速度、潤(rùn)滑劑的物理性質(zhì)和運(yùn)動(dòng)副表面的粗糙度等?;瑒?dòng)軸承的設(shè)計(jì)應(yīng)根據(jù)軸承的工作條件,確定軸承的結(jié)構(gòu)類(lèi)型、選擇潤(rùn)滑劑和潤(rùn)滑方法及確定軸承的幾何參數(shù)。

The formation of lubricating film is the basic condition for the normal operation of sliding bearing. The factors affecting the formation of lubricating film include lubrication mode, relative motion speed of moving pair, physical properties of lubricant and surface roughness of moving pair. The design of sliding bearing shall determine the structural type of bearing, select lubricant and lubrication method and determine the geometric parameters of bearing according to the working conditions of bearing.

以上內(nèi)容就是關(guān)于導(dǎo)軌絲杠http://www.idczc.com/的介紹,希望這些內(nèi)容對(duì)大家有所幫助。如果您還有什么疑問(wèn),或者想要了解更多資訊歡迎咨詢(xún)我們官網(wǎng)。我們將竭誠(chéng)為您服務(wù)。

The above content is about the guide screw http://www.idczc.com/ I hope these contents will be helpful to you. If you have any questions or want more information, please consult our official website. We will serve you wholeheartedly.