新聞中心

對(duì)于導(dǎo)軌絲杠這種機(jī)械傳動(dòng)元件的認(rèn)識(shí)

來(lái)源:http://www.idczc.com/ 日期:2023-04-11 發(fā)布人:

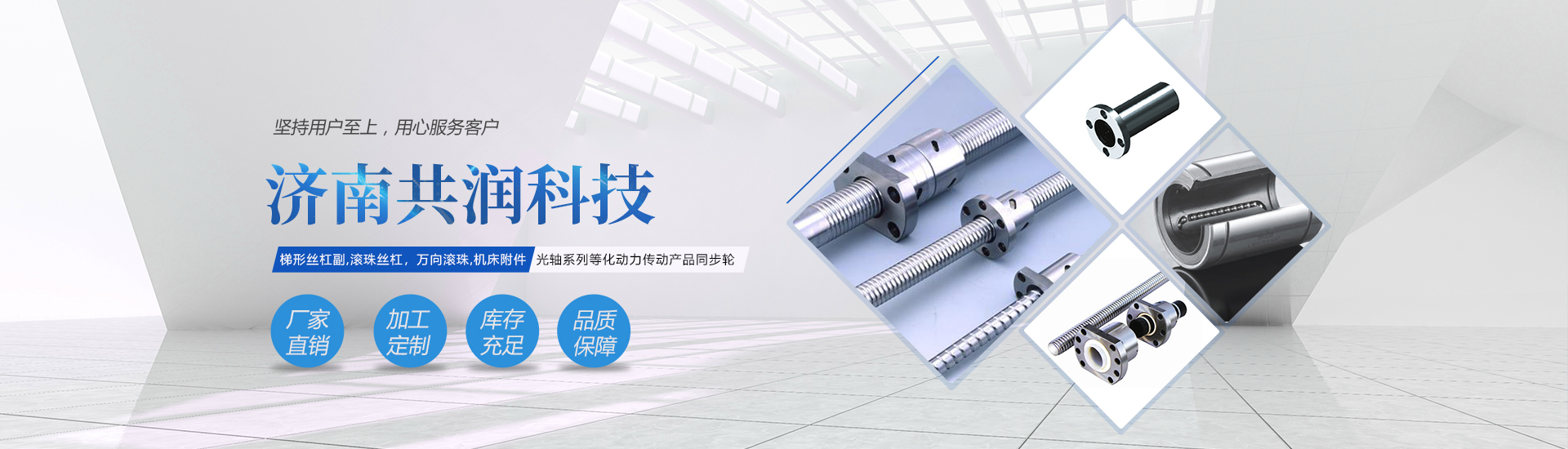

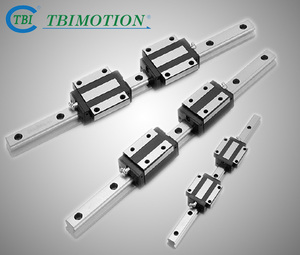

導(dǎo)軌絲杠是一種機(jī)械傳動(dòng)元件,主要用于將旋轉(zhuǎn)運(yùn)動(dòng)轉(zhuǎn)換為直線運(yùn)動(dòng),常用于數(shù)控機(jī)床、自動(dòng)化生產(chǎn)線、機(jī)器人等設(shè)備中。它由絲杠和導(dǎo)軌兩部分組成,絲杠是一種螺旋形的金屬桿,導(dǎo)軌則是一種平面或曲面的金屬條,絲杠和導(dǎo)軌之間通過(guò)滾珠或滑塊等滾動(dòng)元件相互配合,實(shí)現(xiàn)直線運(yùn)動(dòng)。導(dǎo)軌絲杠的主要特點(diǎn)包括以下幾個(gè)方面:

Guide screw is a mechanical transmission component mainly used to convert rotary motion into linear motion, commonly used in CNC machine tools, automated production lines, robots and other equipment. It consists of two parts: a lead screw and a guide rail. The lead screw is a spiral shaped metal rod, while the guide rail is a flat or curved metal strip. The lead screw and the guide rail cooperate with each other through rolling elements such as balls or sliders to achieve linear motion. The main characteristics of guide screw include the following aspects:

1.高精度:導(dǎo)軌絲杠的制造精度高,能夠?qū)崿F(xiàn)高精度的直線運(yùn)動(dòng)。

1. High precision: The manufacturing accuracy of the guide screw is high, which can achieve high-precision linear motion.

2.高剛性:導(dǎo)軌絲杠的結(jié)構(gòu)緊湊,具有高剛性,能夠承受較大的負(fù)載。

2. High rigidity: The guide screw has a compact structure and high rigidity, which can withstand large loads.

3.高能效率:導(dǎo)軌絲杠的滾動(dòng)元件能夠減小摩擦阻力,提高傳動(dòng)效率。

3. High energy efficiency: The rolling element of the guide screw can reduce frictional resistance and improve transmission efficiency.

4.長(zhǎng)壽命:導(dǎo)軌絲杠的滾動(dòng)元件采用高強(qiáng)度材料制造,具有較長(zhǎng)的使用壽命。

4. Long service life: The rolling elements of the guide screw are made of high-strength materials, which have a long service life.

5.低噪音:導(dǎo)軌絲杠的滾動(dòng)元件能夠減小摩擦噪音,使其運(yùn)行更加平穩(wěn)、安靜。

5. Low noise: The rolling element of the guide screw can reduce friction noise, making its operation smoother and quieter.

導(dǎo)軌受力會(huì)導(dǎo)致接觸變形、局部變形和自身變形。觸點(diǎn)變形是由于導(dǎo)軌面的微觀不均勻性引起的;局部變形通常發(fā)生在應(yīng)力集中的地方;導(dǎo)軌本身變形是指導(dǎo)軌受外載后,整體變形,與導(dǎo)軌的材料、布置有關(guān)。直接影響導(dǎo)軌表面之間的平行度和垂直度。直接影響機(jī)床的定位精度、重復(fù)定位精度等精度指標(biāo)。導(dǎo)軌表面粗糙度主要取決于導(dǎo)軌的材料、硬度和工藝。

The force on the guide rail can cause contact deformation, local deformation, and self deformation. Contact deformation is caused by the micro non-uniformity of the guide rail surface; Local deformation usually occurs in areas of stress concentration; The deformation of the guide rail itself refers to the overall deformation of the guide rail after being subjected to external loads, which is related to the material and layout of the guide rail. Directly affects the parallelism and verticality between the surfaces of the guide rails. Directly affects the accuracy indicators of the machine tool, such as positioning accuracy and repeated positioning accuracy. The surface roughness of the guide rail mainly depends on the material, hardness, and process of the guide rail.

總的來(lái)說(shuō),導(dǎo)軌絲杠是一種高精度、高剛性、高能效率、長(zhǎng)壽命、低噪音的機(jī)械傳動(dòng)元件,廣泛應(yīng)用于各種機(jī)械設(shè)備中,對(duì)于提高設(shè)備的精度和穩(wěn)定性具有重要作用。您有需求就來(lái)我們網(wǎng)站http://www.idczc.com咨詢吧!

Overall, guide screw is a mechanical transmission component with high precision, high rigidity, high energy efficiency, long service life, and low noise. It is widely used in various mechanical equipment and plays an important role in improving the accuracy and stability of the equipment. Come to our website if you have any needs http://www.idczc.com Consult!